SERVICES

At Üçelsan Plastic Injection and Mould LTD Co. We are committed to ensuring that you are given high quality services whenever you do business with us.

PLANNING AND DESIGN

PLANNING AND DESIGN

Plastic injection and injection moulding starts with planning and design. The more meticulous the planning and design, the better controlled and predictable the quality will be.

In the planning and design of plastic injection moulding, there are some pertinent questions that must be adequately answered for a seamless manufacturing process to be possible. “How is the part to be used?” “How does it fit to other parts in the assembly?”, “What loads will it experience when in use?”.

Apart from functional and structural issues, processing issues play a large role in the design of an injection moulded plastic part. How the molten plastic enters, fills, and cools within the cavity to form the machine part largely determines what form the features in that part will take. At Üçelsan Plastic Injection and Mould LTD Co, are ready to offer our planning and design expertise at the request of our clients.

MOULD MANUFACTURING

Benefits of Moulds;

We started mould manufacturing in 2006 and manufactured over 600 moulds, mostly plastic injection moulds and metal injection moulds.

- Mass production is easy.

- Manpower per job in production is low.

- Production rate of moulded parts is high.

- Moulded parts do not need to be reworked.

- During the production phase, the moulded part dimensions are controlled within the desired limits.

- It is possible to produce very small parts that cannot be produced by other methods.

- The production of parts in different forms is economical.

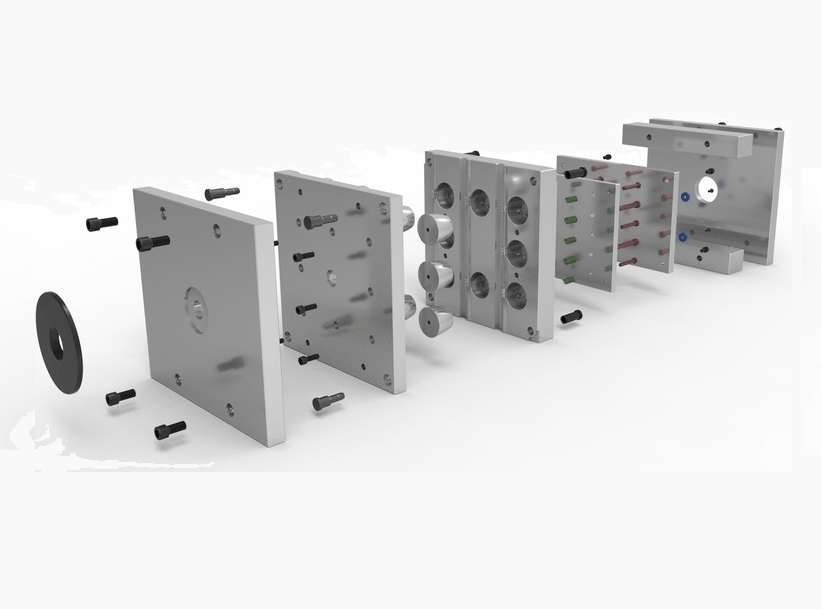

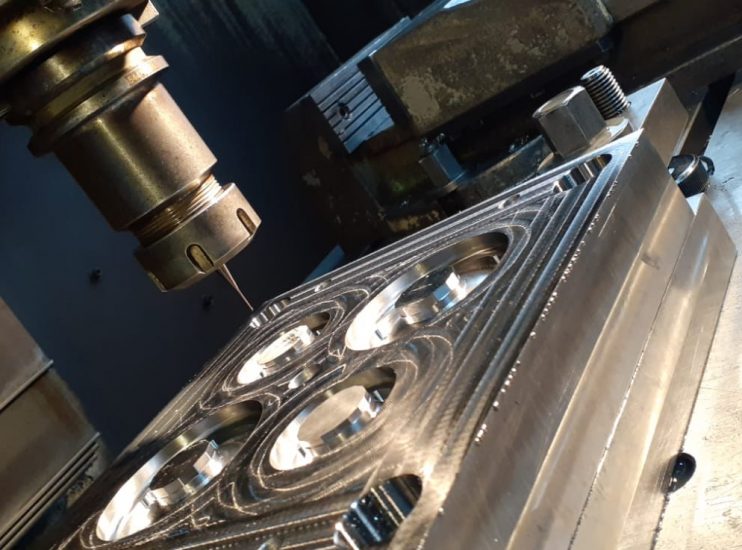

MOULD MANUFACTURING Process

Types of moulds

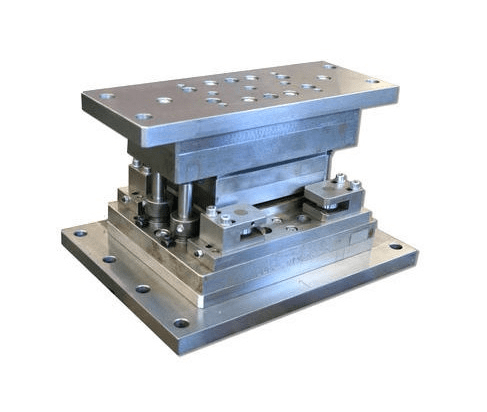

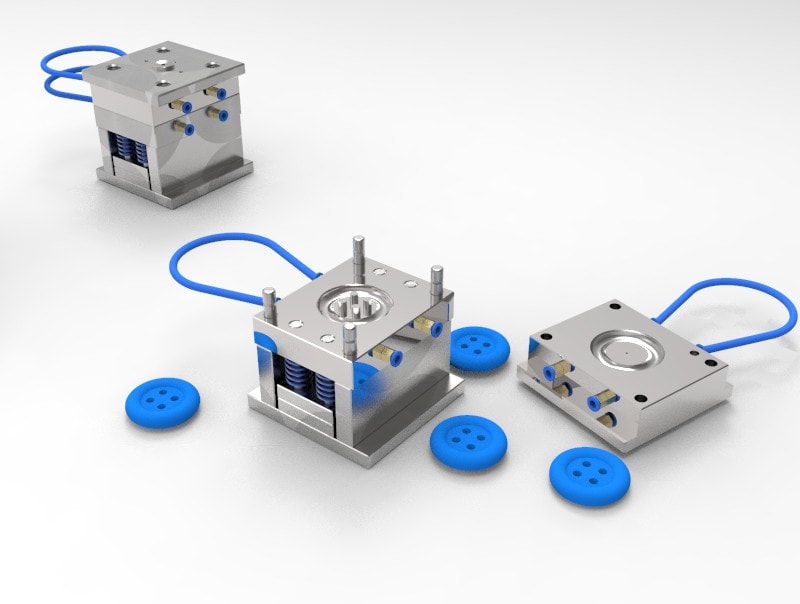

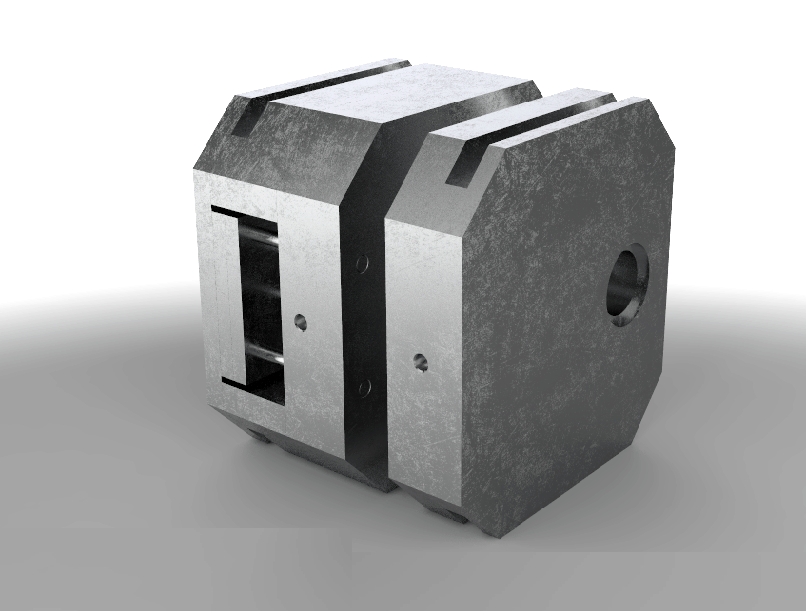

We fabricate moulds of every shape and kind of injections. We make the moulds and test injection moulds on our machines to certify that moulds are working flawlessly. We use softwares as Solidworks (CAD) for designing products and moulds then also Machining Strategist (CAM) to code for CNC machines. Our experience is mostly for plastic injection moulds and metal injection moulds.

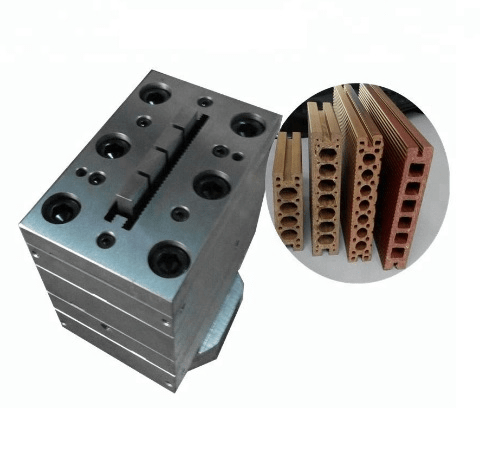

Plastic injection moulds

injection moulds

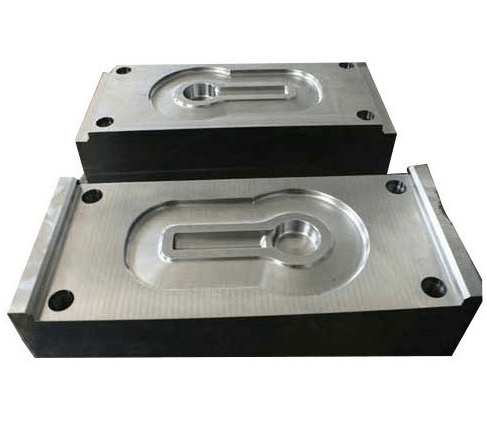

Metal injection moulds

injection moulds

PLASTIC INJECTION

We manufacture a wide range of materials which are indispensable in everyday life and the functioning of human activities. These products include furniture plastics, plastic parts of door/window handles,plastic components of curtain rail systems and general household utilities, electronics enclosures.

Plastic injection moulding is useful manufacturing type for providing large amounts of plastic materials in a short time.The plastic injection process is a quite complex one and the manufacturer has to take care in utilizing the right personnel to operate the machines. Other factors which we ensure are in line with high production quality include;

- Clamping pressure: Clamping pressure also known as tonnage is an important factor in the injection moulding operation. We always do our due diligence in using the machine that matches the kind of clamping pressure required for each job as clamping pressure varies for each machine.The application of tonnage is of great importance to us because it is a critical factor we have to be accurate about in order to make sure we avoid quality complications when we fabricate.

- Melt Flow Index: The melt flow index (MFI) is closely related to the tonnage and it is the measure of the viscosity or ease of flow of the liquid plastic polymer. Different plastics have varying melt flow indexes. We analyze this factor to ensure we deliver top notch results on every occasion.